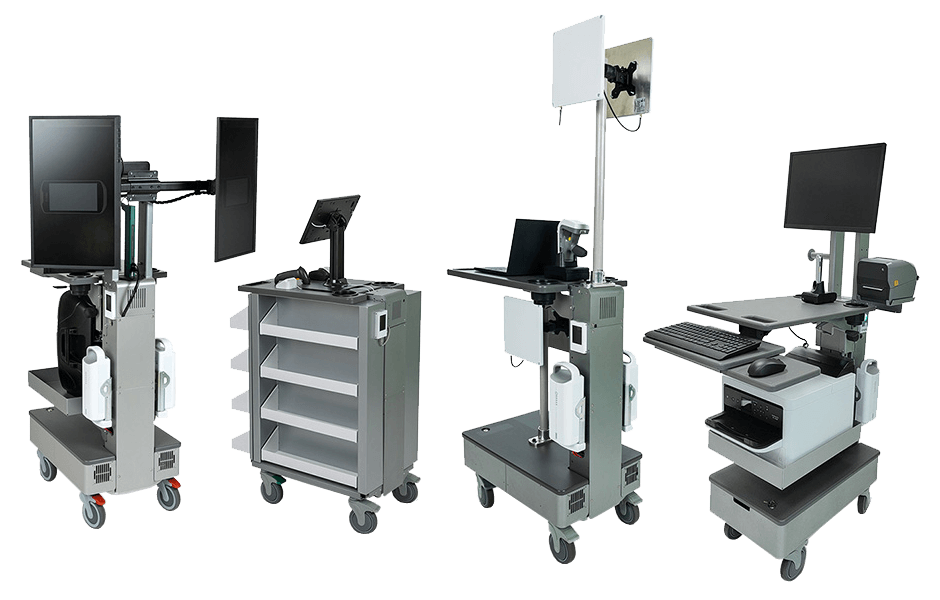

Cleanroom PowerStations are cleanroom-approved computer carts made with a stainless-steel frame and angular design for easy sanitization. Lightweight and ergonomic, these carts that feature uninterruptible instant-swap batteries provide 100% uptime. Ideal for strenuous environments, this cleanroom cart is designed for the rigorous standards of Good Manufacturing Practice (GMP) for Class I cleanroom environments. They come with a sealed monitor bridge for a 24″ monitor, battery and service compartment with a sealing door for electronic components and IT equipment, sealed IEC AC receptacle and Ethernet port. This design allows for seamless electronic batch, production, and laboratory data collection at the point of task.

Mobile Cleanroom Cart Features

- Ergonomic and Lightweight

- LFP battery Chemistry

- 100% Uptime Percentage

- Internal Backup Battery

- Optional Standalone Remote Charger for Off-cart Charging

- 2-Hour Recharge Time

- 250-500 Wh Modular Batteries

- Lightweight 6lb Batteries

- Easy Validation in Class A Cleanroom Environment

- Stainless Steel grade 304 material

- Ethernet and WiFi Capability

Mobile Cleanroom Cart Specifications

- Dimensions 61″H x 24″W x 24″L

- Sealed Monitor Bridge for 24″ Monitor

- Battery and Service Compartment With Sealing Door for Electrical Components and IT Equipment

- Sealed IEC AC Receptacle and Ethernet Port

- Electronic Height Adjustment from 830mm (32.5”) to 1000mm (40”)

- Ventilation with MERV 17 Filters for Electrical Components

- Swivel, Tracking, and Locking Casters

- Printer Shelf for Small Industrial Thermal Printers

- Integrated Barcode Scanner Bracket

- Description

-

Cleanroom PowerStation: Mobile Cleanroom Carts for Class I Cleanroom Environments

Cleanroom PowerStations are cleanroom-approved computer carts made with a stainless-steel frame and angular design for easy sanitization. Lightweight and ergonomic, these carts that feature uninterruptible instant-swap batteries provide 100% uptime. Ideal for strenuous environments, this cleanroom cart is designed for the rigorous standards of Good Manufacturing Practice (GMP) for Class I cleanroom environments. They come with a sealed monitor bridge for a 24″ monitor, battery and service compartment with a sealing door for electronic components and IT equipment, sealed IEC AC receptacle and Ethernet port. This design allows for seamless electronic batch, production, and laboratory data collection at the point of task.

- Features

-

Mobile Cleanroom Cart Features

- Ergonomic and Lightweight

- LFP battery Chemistry

- 100% Uptime Percentage

- Internal Backup Battery

- Optional Standalone Remote Charger for Off-cart Charging

- 2-Hour Recharge Time

- 250-500 Wh Modular Batteries

- Lightweight 6lb Batteries

- Easy Validation in Class A Cleanroom Environment

- Stainless Steel grade 304 material

- Ethernet and WiFi Capability

- Specifications

-

Mobile Cleanroom Cart Specifications

- Dimensions 61″H x 24″W x 24″L

- Sealed Monitor Bridge for 24″ Monitor

- Battery and Service Compartment With Sealing Door for Electrical Components and IT Equipment

- Sealed IEC AC Receptacle and Ethernet Port

- Electronic Height Adjustment from 830mm (32.5”) to 1000mm (40”)

- Ventilation with MERV 17 Filters for Electrical Components

- Swivel, Tracking, and Locking Casters

- Printer Shelf for Small Industrial Thermal Printers

- Integrated Barcode Scanner Bracket

The Definitive Buyer’s Guide to Selecting the Right Mobile Workstation

Download our Buyer’s Guide to understand why it’s important to evaluate mobility, functionality, ergonomics and customization options before purchasing a mobile cart.

The MPower LFP Battery System

DTG’s LFP (lithium iron phosphate) battery chemistry is the safest, most powerful, and cleanest energy source available, providing long lasting and fast charging power that exceeds the rigorous demands of GMP for Class I cleanroom environments.

- Battery Runtime: 8-10 Hours

- Recharge in 2 Hours

- Power Monitor Panel to View Battery Life

- Uninterruptible Instant-Swap Batteries

Affordable and Customizable Cleanroom Computer Cart Solutions

Our cleanroom carts are ideal for manufacturers that need a mobile cart to mobilize technology in a wide range of sterile settings, empowering their workforce to complete activities at the point of task. From an initial needs assessment to provide a consultative plan to optimize workflows, our Six Sigma approach to lean manufacturing enables us to produce and deliver a working prototype – with no NRE commitment – in 30 days. Partner with our design and process engineers to develop a custom cleanroom cart that meets the unique needs of your cleanroom environment.